High pressure die casting machines

Our high pressure die casting machines offer rock-steady, rigid and solid performance ensuring uptime, consistent production and on-time delivery of high quality light alloy castings to your customers.

Our two platen toggle free die casting machines are extremely flexible - they adapt to different working conditions improving your productivity. Toggle free high pressure die casting machines are ideal for a diverse complex casting production and when the die is frequently changed.

Our three platen die casting machines with toggle are solid, reliable and ensure high productivity cycle times. We've engineered the IPr model to have larger platens to meet the increasing demands for the production of aluminium structural parts.

Read more detail below.

Italpresse Gauss is a global die casting technology leader offering the highest quality die casting machines, automated work cells and expert support services.

TF Two Platen Toggle Free Die Casting Machines

IP & IPr Three Platen Die Casting Machines with Toggle

The TF series of toggle free die casting machines includes a wide range of models with closing forces from 1000 to 5700 tonnes. Our TF toggle free die casting machines are reliable, rigid and flexible.

Key Benefits

- Closing force from 1000 to 5700 tonnes

- Two platen toggle free machine

- SC 3.0 shot end system for absolute injection precision and speed

- Compensates for geometrical imperfection of the die and its thermal expansion, making it extremely flexible

KEY FEATURES

The TF toggle free die casting machines are reliable, rigid and flexible.

Reliable: the absence of the connecting rod system and the reaction platen makes the structure leaner, reducing the number of wear parts.

Rigid: the bigger and shorter tie bars make the machine extremely rigid, ensuring greater die closure for improved casting quality and minimal scrap rate.

Flexible: thanks to 4 independent nuts, the TF die casting machine is able to compensate for geometrical imperfection of the die and its thermal expansion, adapting to different working conditions.

Compact: reduced footprint with the same closing force as the die casting machines with toggle.

Quality: high quality machine construction, made of forged or cast steel platen with coating to increase hardness, and special steel alloy tie bars.

Precise: equipped with SC 3.0 shot end system to maintain absolute consistency and repeatability of the shot, ensuring highest quality of the casting.

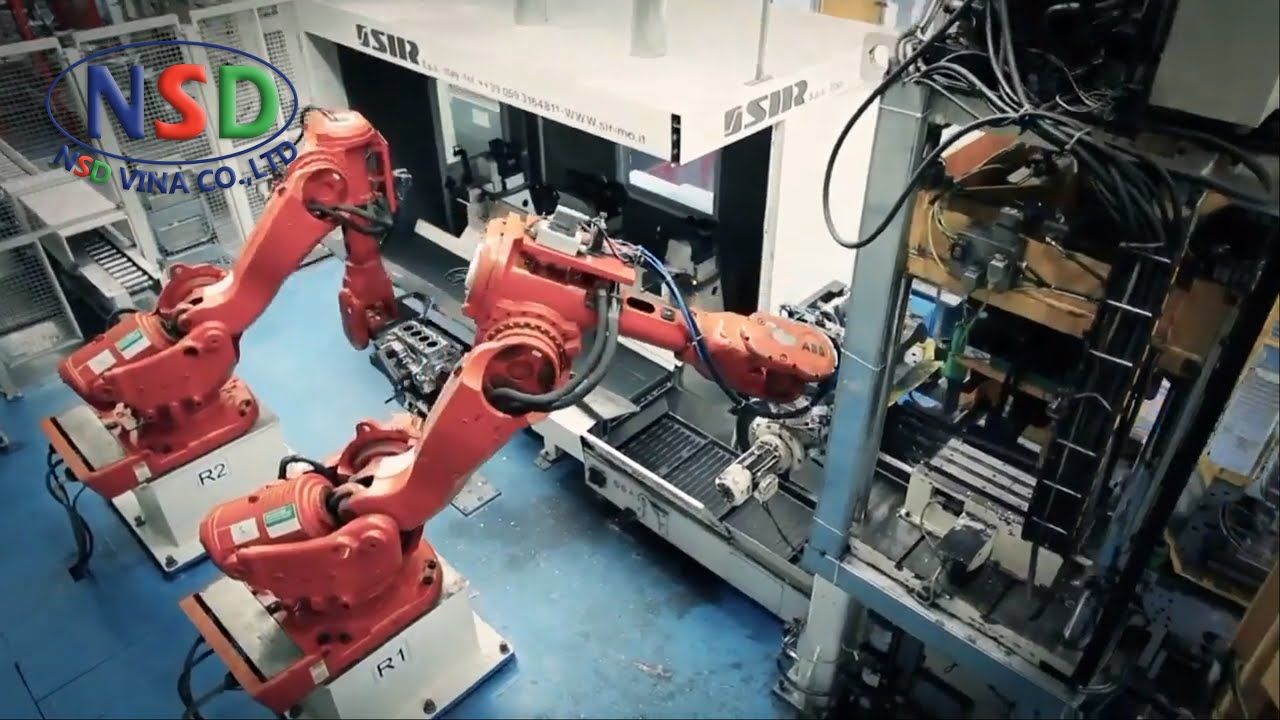

The TF die casting machine can be supplied as an automated solution: a fully automated cell that integrates all peripheral devices, from the furnace to automatic deburring with pieces ready for machining.

Medium size cold chamber toggle free die casting machines

| Cold Chamber | TF Series | TF 1000 | TF 1350 | TF 1650 | TF 1850 | TF 2150 |

| Closing force | kN | 9810 | 13243 | 16186 | 18148 | 21090 |

| Injection force (with 0/25 bar backpressure) | kN | 1015 / 892 | 1150 / 1011 | 1294 / 1137 | 1470 / 1298 | 1704 / 1505 |

| Injection stroke | mm | 740 | 740 | 800 | 900 | 1000 |

| Platens dimensions | mm | 1520 x 1520 | 1785 x 1785 | 1960 x 1960 | 2200 x 2200 | 2230 x 2260 |

| Distance between tie-bars | mm | 950 x 950 | 1050 x 1050 | 1150 x 1150 | 1300 x 1300 | 1350 x 1350 |

| Min. /Max . die height | mm | 550 / 1000 | 600 / 1040 | 700 / 1150 | 800 / 1210 | 900 / 1400 |

| Max. moving platen stroke | mm | 1300 | 1400 | 1500 | 1650 | 1800 |

| Ejection force | kN | 486 | 574 | 574 | 574 | 716 |

| Central ejection stroke | mm | 200 | 240 | 255 | 280 | 300 |

| Max. surface area (with pressure on metal 40 MPa) | cm2 | 2450 | 3310 | 4040 | 4535 | 5270 |

| Max. shot weight | kg | 19 | 21.8 | 23.6 | 26.5 | 37.8 |

| Motor rating | kW | 55 | 2 x 37 | 2 x 37 | 2 x 55 | 2 x 55 |

| Machine weight | t | 48.5 | 67 | 96 | 116 | 144.5 |

| Overall dimensions (length x width x height) | mm | 9090 x 3460 x 3540 | 9225 x 4060 x 3750 | 9667 x 4320 x 4300 | 11120 x 4780 x 4690 | 11775 x 4930 x 4685 |

Subject to technical alterations

Large size cold chamber toggle free die casting machines

| Cold Chamber | TF Series | TF 2500 | TF 2700 | TF 3060 | TF 3500 | TF 4400 | TF 5700 |

| Closing force | kN | 24525 | 26487 | 30019 | 34335 | 43164 | 56000 |

| Injection force (with 0/25 bar backpressure) | kN | 1704 / 1505 | 2135 / 1885 | 2135 / 1885 | 2818 / 2489 | 2818 / 2489 | 3320 / 3040 |

| Injection stroke | mm | 1000 | 1250 | 1250 | 1250 | 1500 | 1600 |

| Platens dimensions | mm | 2535 x 2535 | 2535 x 2535 | 2880 x 2880 | 3060 x 3060 | 3200 x 3200 | 3500 x 3500 |

| Distance between tie-bars | mm | 1550 x 1550 | 1550 x 1550 | 1700 x 1700 | 1780 x 1780 | 1850 x 1850 | 2000 x 2000 |

| Min. /Max . die height | mm | 900 / 1500 | 900 / 1800 | 1100 / 1650 | 1200 / 1800 | 1300 / 2000 | 1400 / 2400 |

| Max. moving platen stroke | mm | 2000 | 2450 | 2000 | 2100 | 2500 | 3300 |

| Ejection force | kN | 716 | 716 | 996 | 996 | 996 | 1196 |

| Central ejection stroke | mm | 300 | 300 | 325 | 350 | 400 | 400 |

| Max. surface area (with pressure on metal 40 MPa) | cm2 | 6130 | 6620 | 7505 | 8585 | 10780 | 14000 |

| Max. shot weight | kg | 42.4 | 59.1 | 59.1 | 65.4 | 78.5 | 110 |

| Motor rating | kW | 2 x 75 | 2 x 90 | 2 x 110 | 2 x 110 | 2 x 160 | 4 x 90 |

| Machine weight | t | 167 | 171 | 216 | 240 | 296 | 350 |

| Overall dimensions (length x width x height) | mm | 12140 x 5000 x 4947 | 13611 x 5220 x 4910 | 14230 x 5400 x 5220 | 14780 x 5600 x 5830 | 16960 x 6000 x 5930 | 17700 x 6500 x 6300 |

Subject to technical alterations

Applications

High pressure die casting machines are ideal for a diverse complex casting production and when the die is frequently changed.

Some applications include:

Automotive parts: Engine blocks, gearboxes, oil sumps, engine support, structural parts (battery housing, car roof, shot tower, pillars).

Other industries: Radiators for household heating, escalator steps, chassis and components for electronic devices, telecommunication components, household appliances, electric motors.

FOR MORE INFORMATION

Write to us an email to info@nsdvn.com and our team will contact you. We want to offer you the best advice.

Contact us

Write to us an email to info@nsdvn.com and our team will contact you. We want to offer you the best advice.

Contact us